The Ultimate Guide to H2S Test Kits

Hydrogen sulfide (H2S) is a colorless, flammable gas with a characteristic odor of rotten eggs. It is not only hazardous but also poses significant health risks when present in high concentrations. Therefore, understanding how to test for H2S and utilizing an H2S test kit effectively is essential for various industries, including oil and gas, wastewater treatment, and environmental monitoring. This comprehensive guide will explore what H2S test kits are, their importance, types available, and how to use them properly.

What is an H2S Test Kit?

An H2S test kit is a specialized set of tools designed to detect the presence and concentration of hydrogen sulfide in the environment. These kits are crucial for ensuring safety in workplaces where H2S may be present. They typically include:

- Detection tubes

- Colorimetric test strips

- Electronic sensors or meters

- Calibration gases

- Protective gear

Choosing the right type of test kit depends on the specific needs of the user, the expected concentration levels of H2S, and the environmental conditions of the workspace. Comprehensive knowledge about H2S detection can significantly improve safety outcomes in high-risk environments.

Why is H2S Detection Important?

The importance of detecting hydrogen sulfide cannot be overstated. Here are several compelling reasons for utilizing an H2S test kit:

- Health Risks: H2S is a poison that can lead to symptoms such as headaches, nausea, dizziness, and loss of consciousness. In severe cases, exposure can be fatal.

- OSHA Regulations: Occupational Safety and Health Administration (OSHA) regulates the allowable limits of H2S in workplaces. Having a reliable H2S test kit ensures compliance with these regulations.

- Workplace Safety: Early detection can prevent accidents and save lives. Regular testing of environments where H2S is a risk is crucial.

- Environmental Monitoring: H2S can have devastating effects on local ecosystems. Monitoring its levels helps in environmental conservation efforts.

Types of H2S Test Kits

There are various types of H2S test kits, each designed for different applications. Understanding these types helps in selecting the best option for specific needs:

1. Colorimetric Test Kits

These kits use chemical indicators that change color when they come into contact with hydrogen sulfide. They are straightforward to use and can provide quick results. Commonly found in personal monitoring devices, they are useful for field testing.

2. Electronic H2S Detectors

These are sophisticated devices that provide real-time monitoring of H2S levels. They are sensitive and can detect very low concentrations, making them ideal for environments where safety is paramount.

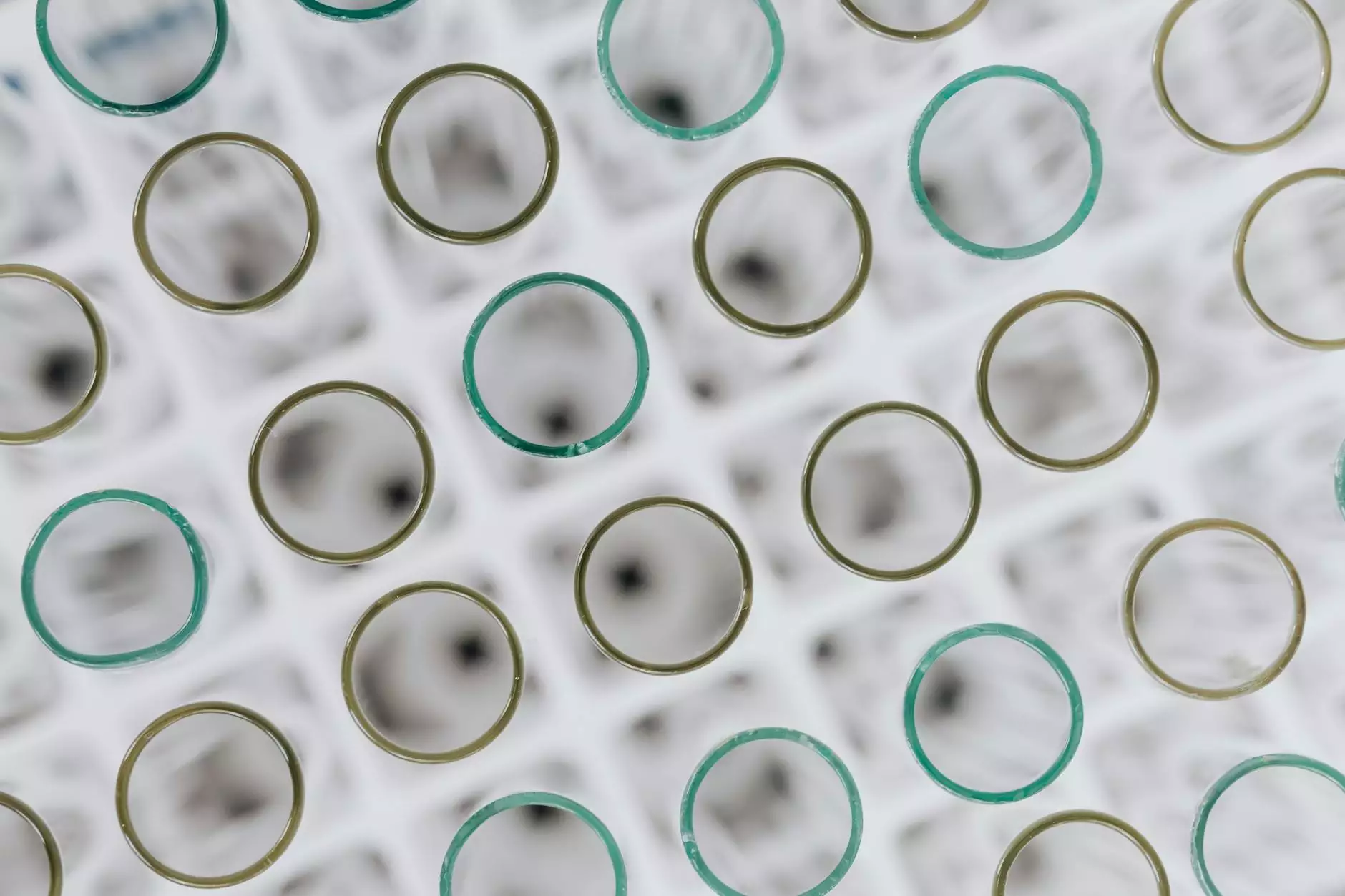

3. Gas Detection Tubes

Gas detection tubes are often used for spot testing. They can provide immediate visual indication of H2S levels through a chemical reaction that produces a colored line on the tube.

How to Use an H2S Test Kit

Using an H2S test kit involves several steps, each of which is crucial for obtaining accurate results. Here’s a detailed process:

Step 1: Prepare the Testing Area

Ensure that the area is clear of any obstructions and that you have the necessary personal protective equipment (PPE) on, including gloves and safety goggles. This is vital in case H2S is present.

Step 2: Follow the Manufacturer's Instructions

Each test kit will come with specific instructions from the manufacturer. Always read and follow these guidelines to ensure safety and accuracy. This may include:

- Calibration of electronic sensors

- Activation procedures for test strips or tubes

Step 3: Conduct the Test

Apply the appropriate testing method based on the kit you are using:

- For Colorimetric Kits: Dip the test strip into the sample and observe for color changes.

- For Electronic Detectors: Turn the device on and monitor the readings as indicated on the display.

- For Gas Detection Tubes: Break the ends of the tube and inhale the sample according to instructions.

Step 4: Interpret the Results

Carefully compare your results against the color charts (for chemical tests) or read the digital display (for electronic sensors) to determine the concentration of H2S. Always record your findings for future reference and analysis.

Maintenance and Calibration of H2S Test Kits

Regular maintenance and calibration are essential to ensure that your H2S test kit operates effectively. Here are some important tips:

- Calibration: Follow the manufacturer's instructions for calibrating electronic sensors regularly, as this ensures accuracy in readings.

- Storage: Store your test kits in a cool, dry place to prevent degradation of chemicals and components.

- Inspection: Routinely inspect your test kits for wear and tear, replacing any damaged parts immediately.

Conclusion

In conclusion, understanding hydrogen sulfide and its dangers is critical for maintaining workplace safety and protecting health. Utilizing an H2S test kit not only helps in compliance with safety regulations but also plays a vital role in environmental protection. By following the guidelines laid out in this article, businesses can make informed decisions about H2S detection and ensure a safer working environment for all employees.

For more information on H2S training and safety in the workplace, please visit our website: h2sonlinetraining.com.